|

The WarCamp Line - May 2003 |

|

Z3 Glove box Ė The final fix By: Warren Campbell As much as we love our Z3ís, the flimsy, rattling glove box has been a source of irritation for at least 100,000 of my 125,000 miles. Drivers have proposed quite a number of fixes over the years, but in my opinion, they ignore the basic problem. Basic problem:

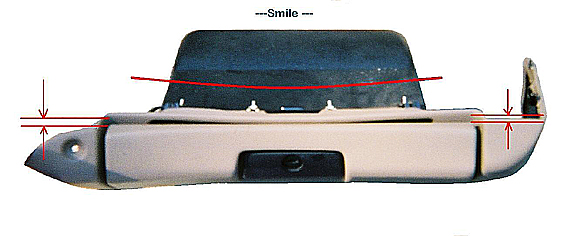

As you can see in this photo, the door of the glove box remains straight while the frame sags in the middle. See that smiley face above the door? Itís not original OEM! This leaves the glove box loose. The bad boy causing this is

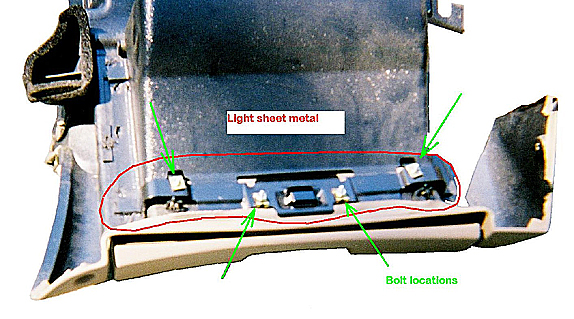

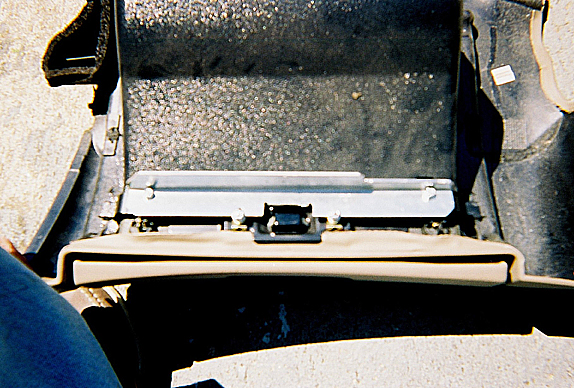

a very light piece of sheet metal that canít support the weight of the glove box along, much less should you put anything in it! Some of the old fixes for this problem had you adding washers to make the latch fit tighter, but all this did was to cause this bow in the frame to grow more. Not a good solution. R&D: I knew the solution would be to either replace this sheet metal with something more substantial or add a heaver piece of metal in this area. I choose to add a piece of 1x1x11guage angle (11 gauge is about 0.100" or 3/32"). The above photo shows the light sheet metal (in red) as it comes from Spartanburg as well as the 4 bolts (in green) used to hold the new heavy metal. Important Note: Even though I used an angle to fix my glove box, Iím convinced that flat bar would be better. Youíre wondering why I went ahead with the angle. Keep in mind that this project required me to not only make several trips to the hardware store, but to get this all to fit in the very tight space above the glove box, I had to install and remove the box probably six times as I continued to trim the angle so that it would fit. By the end of the day, I wasnít going back to the hardware store and starting over with the flat bar! Mine has angle but the 1"x11ga flat bar would be much better. Also, you might be tempted to use something heaver than the 11 gauge metal. Donít do it! There just isnít room in there. FredR has checked some of the various Z3 boxes and found that they are all the US glove boxes are the same. This should work on all models in the US. Hereís what you do: Visit your local hardware store and get:

Total cost will be about $10.00. Tools needed:

Time to go to work:

Have Fun!

Warren

|

|

For more info contact Warren Campbell

|

|

Jeff Newton - Webmaster |

| Posted: Monday, May 5 2003 |